The potentiometer is a fundamental component in the world of electronics, enabling precise control over voltage or current in a circuit. Whether you're an aspiring electronics enthusiast or a seasoned engineer, understanding the potentiometer pin diagram is crucial. This diagram serves as a visual representation of the potentiometer's internal connections, which is essential for its proper integration into various electronic applications. By mastering this diagram, you can unlock the potential of the potentiometer, allowing for greater flexibility and accuracy in your projects.

At first glance, the potentiometer pin diagram might seem daunting. Yet, with a bit of guidance, you can decipher its intricacies and appreciate its functionality. Typically, a potentiometer has three pins: the first and third pins are connected to a resistive element, while the middle pin connects to a movable wiper. The wiper's position determines the resistance between the first pin and the wiper or the third pin and the wiper. This relationship forms the core principle of the potentiometer's operation, allowing it to adjust voltage levels smoothly and accurately.

In this article, we'll delve into every aspect of the potentiometer pin diagram, from its basic structure to its applications in complex circuits. We'll explore the different types of potentiometers, their unique characteristics, and how each type affects the pin configuration. By the end of this comprehensive guide, you'll possess the knowledge to effectively utilize potentiometers in any electronic project, enhancing both your understanding and practical skills in electronics.

Table of Contents

- Basic Structure of a Potentiometer

- Types of Potentiometers and Their Pin Configurations

- Working Principle of a Potentiometer

- Applications of Potentiometers

- How to Read a Potentiometer Pin Diagram

- Troubleshooting Common Potentiometer Issues

- Advantages and Limitations of Potentiometers

- Potentiometer vs. Rheostat

- Digital Potentiometers and Their Pin Diagrams

- Integrating Potentiometers into Circuits

- Maintaining and Calibrating Potentiometers

- Frequently Asked Questions

- Conclusion

Basic Structure of a Potentiometer

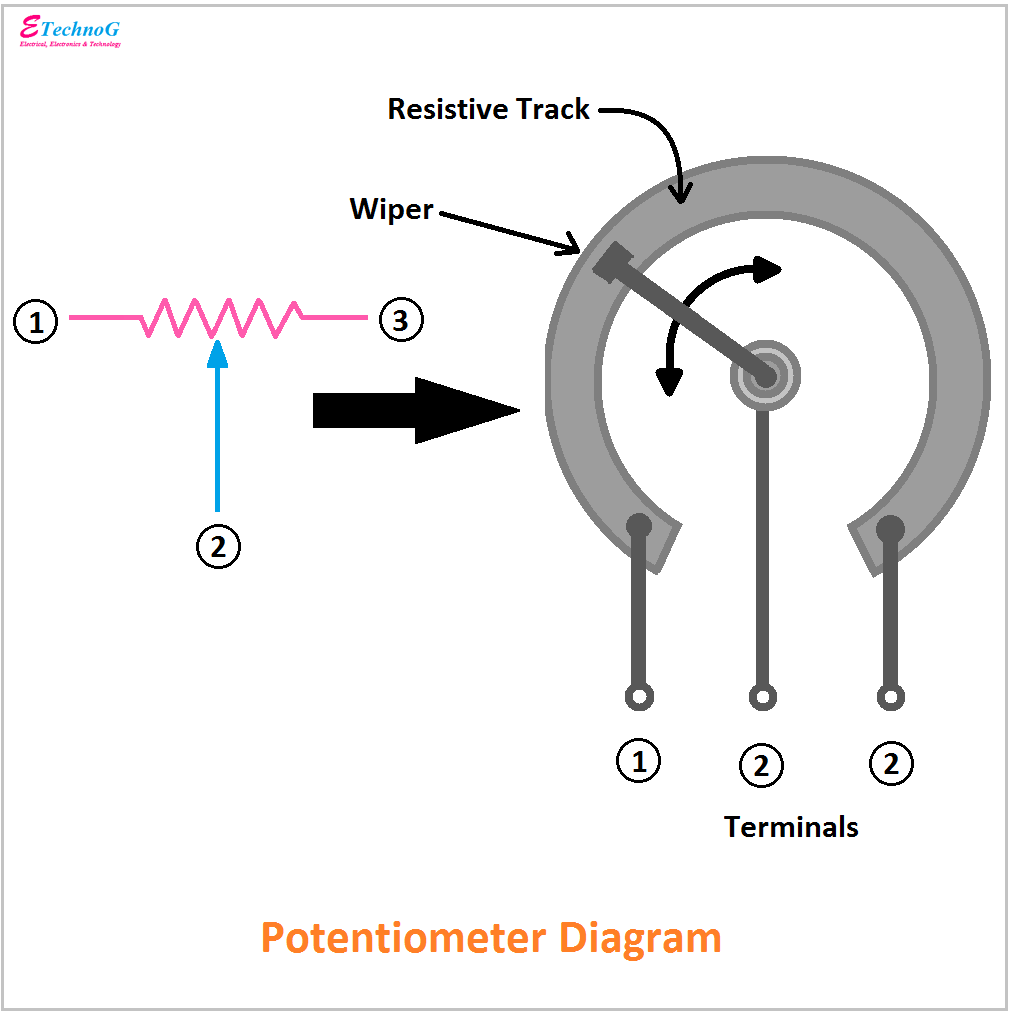

A potentiometer is a three-terminal resistor with a sliding or rotating contact that forms an adjustable voltage divider. The basic structure consists of a resistive element, a wiper, and three terminals or pins. These pins are typically aligned in a linear or rotary configuration, depending on the type of potentiometer. Understanding the layout and function of these components is essential to grasp how potentiometers work in electronic circuits.

The resistive element is the core part of the potentiometer, usually made from carbon, cermet, or conductive plastic. This element creates a path for the electrical current, with its resistance value determining the overall range of the potentiometer. The wiper is a movable contact that slides along the resistive element. As it moves, it changes the resistance between the wiper and each of the outer terminals, thereby adjusting the voltage output.

Terminals and Connections

The three terminals of a potentiometer are crucial for its operation:

- Terminal 1 (Pin 1): One end of the resistive element.

- Terminal 2 (Pin 2): The wiper, which moves along the resistive element.

- Terminal 3 (Pin 3): The other end of the resistive element.

In a typical potentiometer setup, terminals 1 and 3 are connected to the resistive element, while the wiper (terminal 2) moves between them. This configuration allows for the adjustment of resistance and, consequently, the voltage across the wiper.

Types of Potentiometers and Their Pin Configurations

Potentiometers come in various types, each with unique features and pin configurations. The most common types include rotary, linear, and digital potentiometers. Each type is suited for specific applications, and understanding their differences is essential for selecting the right potentiometer for your project.

Rotary Potentiometers

Rotary potentiometers are the most widely used type, featuring a circular resistive element and a rotating wiper. The pin configuration for rotary potentiometers is straightforward, with the three pins aligned linearly at the back of the component. These potentiometers are ideal for applications requiring smooth and continuous adjustment, such as volume controls and dimmer switches.

Linear Potentiometers

Linear potentiometers, also known as slide potentiometers, have a straight resistive track and a sliding wiper. Their pin configuration is similar to rotary potentiometers, but the pins are usually positioned at one end of the component. Linear potentiometers are commonly used in mixing consoles and other equipment where linear motion is preferred.

Digital Potentiometers

Digital potentiometers, or digipots, use digital signals to control resistance. Unlike their analog counterparts, digital potentiometers have additional pins for power supply and control signals. These devices are often used in applications requiring precise and repeatable adjustments, such as automated systems and microcontroller interfacing.

Working Principle of a Potentiometer

The potentiometer operates on a simple principle: as the wiper moves along the resistive element, it divides the voltage between the two outer terminals. This division creates a variable voltage output at the wiper, which can be used to control various electronic functions.

When a voltage is applied across the resistive element (between terminals 1 and 3), the wiper (terminal 2) picks up a fraction of this voltage. The exact value depends on the wiper's position along the resistive track. By adjusting the wiper, the user can change the resistance and the resulting voltage output, allowing for fine-tuned control over connected circuits.

Voltage Divider Formula

The voltage divider formula is a mathematical representation of the potentiometer's function. It can be expressed as:

Vout = Vin * (Rw / (R1 + Rw))

Where:

- Vout is the output voltage at the wiper.

- Vin is the input voltage applied across the resistive element.

- Rw is the resistance from the wiper to one end of the resistive element.

- R1 is the resistance from the other end of the resistive element to the wiper.

Applications of Potentiometers

Potentiometers are versatile components used in a wide range of applications, from simple volume controls to complex sensor systems. Their ability to provide precise and adjustable resistance makes them invaluable in various electronic devices and systems.

Audio Equipment

One of the most common applications of potentiometers is in audio equipment, where they are used as volume controls. By adjusting the resistance, potentiometers can smoothly change the audio signal's amplitude, allowing for gradual increases or decreases in volume.

Lighting Controls

Potentiometers are also used in lighting systems, particularly as dimmer switches. By altering the resistance, they can control the amount of current flowing to a light source, thereby adjusting the brightness of the light.

Position Sensing

In industrial and consumer applications, potentiometers are often used as position sensors. By detecting the wiper's position along the resistive track, these potentiometers can provide feedback on the position of a mechanical component, such as a lever or a joystick.

Microcontroller Interfacing

Digital potentiometers are frequently used in microcontroller applications, where they provide a programmable way to adjust resistance. This capability is useful in automated systems, where precise and repeatable adjustments are required.

How to Read a Potentiometer Pin Diagram

Reading a potentiometer pin diagram is a straightforward process once you understand the basic structure and function of the component. The pin diagram provides a visual representation of the potentiometer's internal connections, enabling you to integrate it correctly into your circuit.

Identifying the Pins

The first step in reading a potentiometer pin diagram is to identify the three pins. These are usually labeled as follows:

- Pin 1: One end of the resistive element.

- Pin 2: The wiper, or movable contact.

- Pin 3: The other end of the resistive element.

In most diagrams, these pins are numbered sequentially from left to right or top to bottom. Pay close attention to the pin numbering to ensure accurate connections in your circuit.

Understanding the Connections

Once you've identified the pins, you can use the pin diagram to understand how the potentiometer connects to your circuit. Typically, pins 1 and 3 are connected to the power source, while pin 2 (the wiper) connects to the load or the component you wish to control.

By moving the wiper along the resistive element, you can change the resistance between pins 1 and 2 or pins 2 and 3, thus adjusting the voltage output or current flow in your circuit.

Troubleshooting Common Potentiometer Issues

While potentiometers are generally reliable components, they can encounter issues over time. Common problems include noise, erratic behavior, or complete failure. Understanding these issues and their solutions can help you maintain your potentiometers in optimal condition.

Noisy Output

A noisy output is a common issue with potentiometers, often caused by dirt or wear on the resistive element. This problem can result in crackling or static noise when adjusting the potentiometer. Cleaning the potentiometer with a contact cleaner or replacing it can resolve this issue.

Erratic Behavior

Erratic behavior, such as sudden jumps in resistance or voltage, can occur if the wiper loses contact with the resistive element. This issue can be caused by physical damage or wear. In such cases, replacing the potentiometer is usually the best solution.

Complete Failure

Complete failure of a potentiometer can occur due to a broken wiper or damaged resistive element. If the potentiometer no longer functions, replacing it is necessary to restore proper operation.

Advantages and Limitations of Potentiometers

Potentiometers offer several advantages, including simplicity, versatility, and ease of use. However, they also have limitations that should be considered when selecting them for your projects.

Advantages

Potentiometers are simple and easy to use, making them an ideal choice for beginners and experienced engineers alike. Their ability to provide adjustable resistance allows for precise control over various electronic functions. Additionally, potentiometers are versatile, with applications ranging from audio equipment to industrial sensors.

Limitations

Despite their advantages, potentiometers have limitations. They can wear out over time, leading to issues such as noise or erratic behavior. Potentiometers are also limited in terms of resolution and precision compared to digital alternatives. In applications requiring high precision or reliability, digital potentiometers or other components may be more suitable.

Potentiometer vs. Rheostat

Potentiometers and rheostats are both variable resistors, but they serve different purposes and have distinct characteristics. Understanding the differences between these components can help you choose the right one for your application.

Potentiometers

Potentiometers are primarily used as voltage dividers, with three terminals: two connected to the resistive element and one to the wiper. They are ideal for applications requiring adjustable voltage levels, such as audio volume controls and dimmer switches.

Rheostats

Rheostats, on the other hand, are used to control current and typically have two terminals: one connected to the resistive element and one to the wiper. They are often used in applications requiring high power or current control, such as motor speed controllers and heating elements.

Digital Potentiometers and Their Pin Diagrams

Digital potentiometers, or digipots, offer a modern alternative to traditional potentiometers. These components use digital signals to adjust resistance, providing precise and repeatable control over electronic functions.

Pin Configurations

Digital potentiometers have a more complex pin configuration than their analog counterparts. In addition to the three main pins (similar to a traditional potentiometer), digipots include pins for power supply, ground, and digital control signals. These additional pins enable communication with microcontrollers and other digital devices.

Advantages of Digital Potentiometers

Digital potentiometers offer several advantages, including increased precision, reliability, and programmability. They are ideal for applications requiring automated or remote control over resistance, such as in automated systems or wireless devices.

Integrating Potentiometers into Circuits

Integrating a potentiometer into a circuit involves connecting its pins to the appropriate components and ensuring proper operation. This process requires careful attention to the pin diagram and the specific requirements of your application.

Basic Integration Steps

The following steps outline the basic process for integrating a potentiometer into a circuit:

- Identify the potentiometer's pins using the pin diagram.

- Connect pins 1 and 3 to the power source, ensuring the correct voltage and polarity.

- Connect pin 2 (the wiper) to the component or load you wish to control.

- Test the potentiometer's operation by adjusting the wiper and observing the changes in resistance or voltage.

Maintaining and Calibrating Potentiometers

Regular maintenance and calibration can ensure the longevity and accuracy of your potentiometers. By following best practices, you can prevent issues such as noise and erratic behavior, ensuring reliable performance in your projects.

Cleaning and Inspection

Regular cleaning and inspection of potentiometers can prevent common issues such as noise and erratic behavior. Use a contact cleaner to remove dirt and debris from the resistive element and wiper. Inspect the potentiometer for signs of wear or damage, and replace it if necessary.

Calibration

Calibration involves adjusting the potentiometer to ensure it provides accurate resistance and voltage levels. This process may involve comparing the potentiometer's output to a known reference and making adjustments as needed. Regular calibration can help maintain the accuracy and reliability of your potentiometers in critical applications.

Frequently Asked Questions

Q1: What is the purpose of the potentiometer pin diagram?

A1: The potentiometer pin diagram provides a visual representation of the component's internal connections, helping users integrate it correctly into electronic circuits.

Q2: How do I identify the pins on a potentiometer?

A2: The pins on a potentiometer are typically labeled as Pin 1, Pin 2 (the wiper), and Pin 3. They are usually aligned in a linear or rotary configuration, depending on the type of potentiometer.

Q3: What is the difference between a potentiometer and a rheostat?

A3: Potentiometers are used as voltage dividers with three terminals, while rheostats are used to control current with two terminals. Potentiometers are ideal for applications requiring adjustable voltage levels, while rheostats are suited for high power or current control.

Q4: Can digital potentiometers be used in place of traditional potentiometers?

A4: Yes, digital potentiometers can replace traditional potentiometers in many applications, offering increased precision, reliability, and programmability. However, they require additional pins for digital control signals and power supply.

Q5: How can I prevent noise in potentiometers?

A5: To prevent noise in potentiometers, regularly clean the resistive element and wiper with a contact cleaner. If noise persists, consider replacing the potentiometer or using a digital alternative.

Q6: What are some common applications of potentiometers?

A6: Potentiometers are commonly used in audio equipment as volume controls, lighting systems as dimmer switches, position sensing applications, and microcontroller interfacing for programmable resistance adjustments.

Conclusion

In conclusion, understanding the potentiometer pin diagram is an essential skill for anyone working with electronics. By mastering this diagram, you can effectively integrate potentiometers into your projects, unlocking their full potential for precise control over voltage and current. With a solid grasp of the basic structure, types, and applications of potentiometers, you'll be well-equipped to tackle a wide range of electronic challenges. Remember to consider both the advantages and limitations of potentiometers when selecting them for your projects, and don't hesitate to explore digital alternatives for increased precision and reliability. By following best practices for maintenance and calibration, you can ensure your potentiometers remain in optimal condition, providing reliable performance in all your electronic endeavors.

For further reading and detailed information, you may refer to [this external resource](https://www.electronics-tutorials.ws/resistor/potentiometer.html) on potentiometers, which offers additional insights into their operation and applications.

You Might Also Like

The Comprehensive Guide To Mac OS Yosemite: A Revolutionary Operating SystemThe Intricacies And Insights Into "Be Ur Man": An In-Depth Exploration

The Curious Case Of Target Circle Earnings Disappeared: An In-Depth Analysis

Discovering The Versatile World Of Denim Dress Style

The Fascinating World Of Japanese Kigurumi: An In-Depth Exploration

Article Recommendations

- Usain Bolt Net Worth

- Dd15 Engine

- Projection Of A Onto B

- I Feel So Close To You Right Now Lyrics

- Crazy Rich Asians Opening Scene

- External Thrombectomy

- Strawberry Desserts No Bake

- Ujjain Sightseeing Places

- Terminator Genisys Cast

- Jason Patric